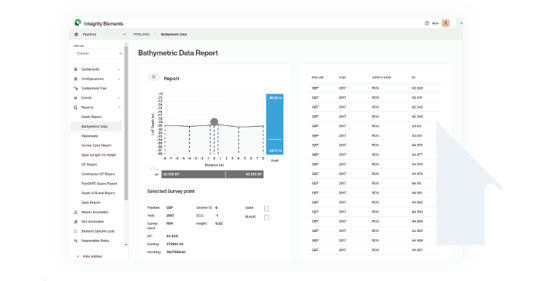

The integrity cycle in today’s pipeline inspection and data management can in many cases exceed both budget cycles and the regulators’ annual reporting requirements. With Aize’s new module Pipeline module in Integrity Elements allowing for rapidly accessible data collection and processing, events can be reviewed sooner, and urgent anomalies can be identified and assessed quicker. This enables decision making in a more proactive rather than today’s more reactive manner.

If you think this beggars belief, we welcome you to join our webinar on the next generation inspection technology to be held 23 September. It is meant for everyone working in renewables, oil and gas and pipeline operations.

The new digital twin co-worker

Aize Integrity Elements stems from our previous integrity management system Coabis, which has helped our clients with integrity management for more than 30 years. It’s now being launched in a faster and more powerful version, with the new module Pipeline Integrity Management as one of four foundation elements. All of Aize’s applications are accessed through our digital twin that allows you to create a sophisticated digital replica of your physical assets.

Lisa Strachan, Senior Pipeline Engineer at Aker Solutions, has 25 years Integrity Management experience, predominately in pipelines and acted as a Subject Matter Expert during the development of the pipeline module.

“Pipeline operators must demonstrate that they are legally compliant with the strict and comprehensive pipeline safety regulations. Failing to properly maintain your pipelines can potentially become catastrophic, posing a risk for both humans and the ecosystems in the surrounding environment. With this in mind, we needed an application that made assessment of the pipeline inspection data way more effective, precise, and sophisticated than it is today”, says Lisa.

Problems that arise are often due to lack of data use, making tasks like forecasting when pipelines are likely to fail and identifying the consequences of gradual changes in the pipelines difficult. These problems are frequently exacerbated by manual processing of the data and the use of many Excel sheets.

“Many of the current inspection campaigns currently require the data to be manipulated in Excel, and it’s a time-consuming job to manually control, sort, analyse and act upon the data gathered during an inspection campaign. It usually takes several months to get a total picture of the condition of the pipeline after an inspection is conducted, due to the several ‘hands’ the data passes through” Lisa explains.

After gathering pipeline data with an inspection vessel, many software applications available today require the data to be processed both offline and online for quality control and anomaly registration in several steps. Each step requires the data to change hands – an action that is repeated on numerous occasions. With the digital twin doing much of the data handling, quality control, sorting and categorising, the number of hands the data passes through can be drastically cut.

“Thanks to the digital twin, the inspection crew can upload the data and blitz through the findings while you sleep. By creating a set of rules for what qualifies to be an anomaly, the software can categorise it for you. This in turn allows the engineers on land to find critical anomalies for the vessel to check out while it’s still on site”, says Lisa.

Unleashing the power of the cloud

Christoffer Nilsen-Aas, Senior Director and Aize’s Product Manager of the Integrity Elements application, is excited to introduce the new software at our upcoming webinar.

“There are many locally installed and tailored solutions out there, where you have one application for pipeline integrity, one for SURF, one for topside integrity, leaving you with several different applications. They don’t necessarily talk to each other and some of the old software is even built on language that’s out of date”, Christoffer explains.

In contrast to cloud services, local systems don’t give you the opportunity to easily scale as you aggregate more data, or the resolution of your video and images goes up. By moving our solutions to the cloud, our customers can easily scale up and increase both storage space and processing power.

“Aize’s digital twin combines over 30 years of competency and experience with the power of cloud computing and lets you access all applications within the same system. By giving you one single source of truth and reducing the number of applications needed to one, you’re also able to reduce your costs significantly”, says Christoffer.

“There’s really no going back once you’ve entered the digital twin. This has opened a completely new world for us who work with pipeline inspection, where we’re able to inspect subsea and topside within the same application. With just a few clicks we can get a holistic view of the condition of the pipeline system, which in turn makes our decisions both quicker and more precise,” Lisa concludes.

Want to know more? Sign up for our next generation inspection software webinar on 23 September.

Post written by Trine Bratt Stølsnes

Trine is the Director and Head of Marketing at Aize, where she combines her passion for marketing strategy with the challenge of shaping how digital twin technology transforms the energy industry. With years of experience in B2B marketing, she is dedicated to driving meaningful change through effective marketing and communication.

Stay in the loop

I’d like to sign up to Aize newsletter