OPERATE AND MAINTAIN ASSETS WITH AIZE

See things differently

to operate better

Manage performance, maintenance, and your operating assets' integrity.

.jpg?width=600&height=400&name=Application%20in%20use%20Aberdeen%2014%20(1).jpg)

Engineering and operational data in one place

Aize combines data visualisation with operational tools and asset intelligence so that the modern industrial operator can optimise workflows, drive efficiency and make confident decisions.

IMPROVE YOUR MODELS

Make brownfield assets shine again

Consolidating engineering information into a new platform requires domain knowledge and not just pattern recognition. That’s why valuable legacy data sources such as P&ID printouts become hot-spotted smart documents in Aize - activating your domain experts in all walks of engineering. Visualising the gaps makes them easier to close.

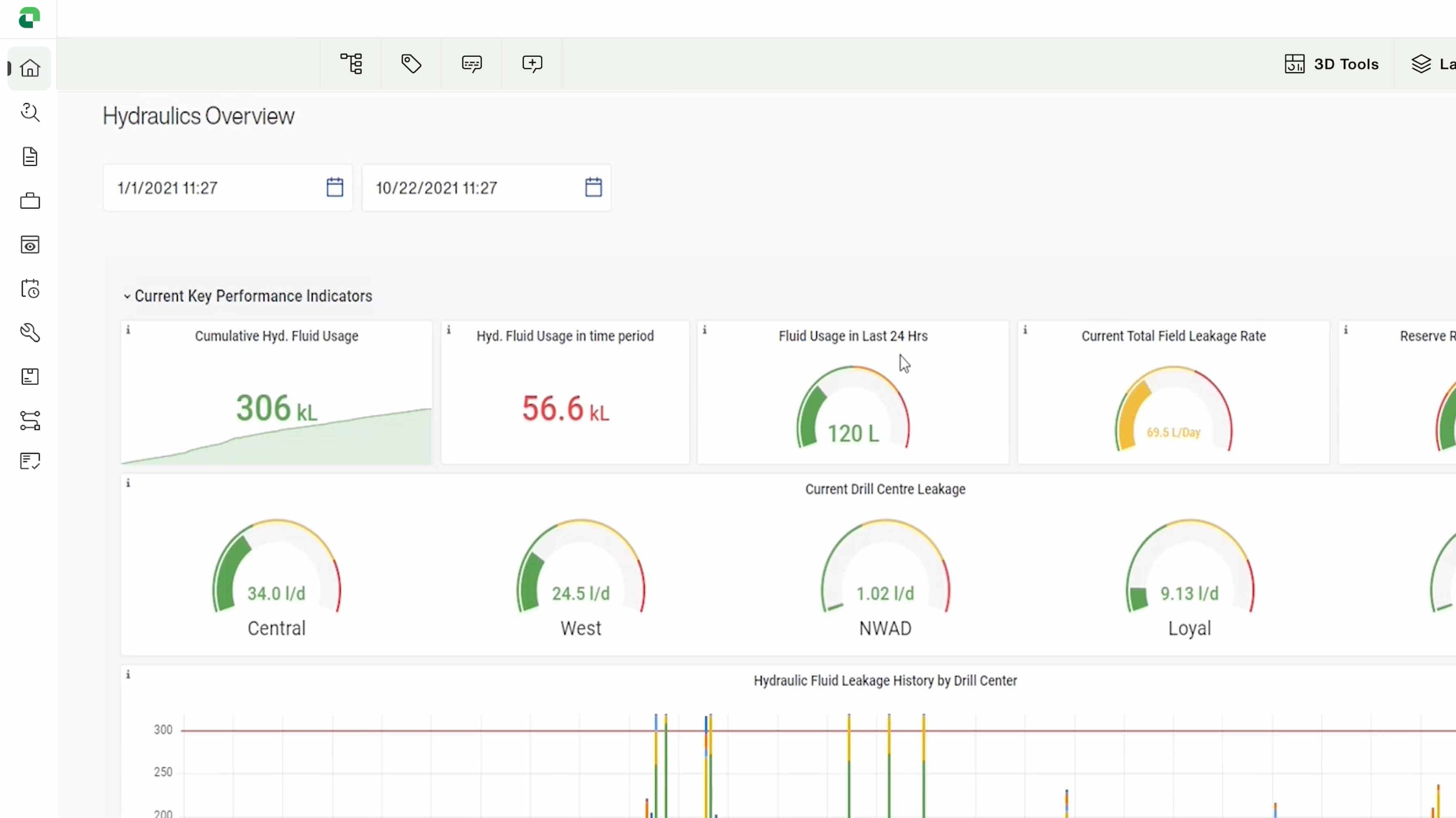

TRUST AND CONTROL

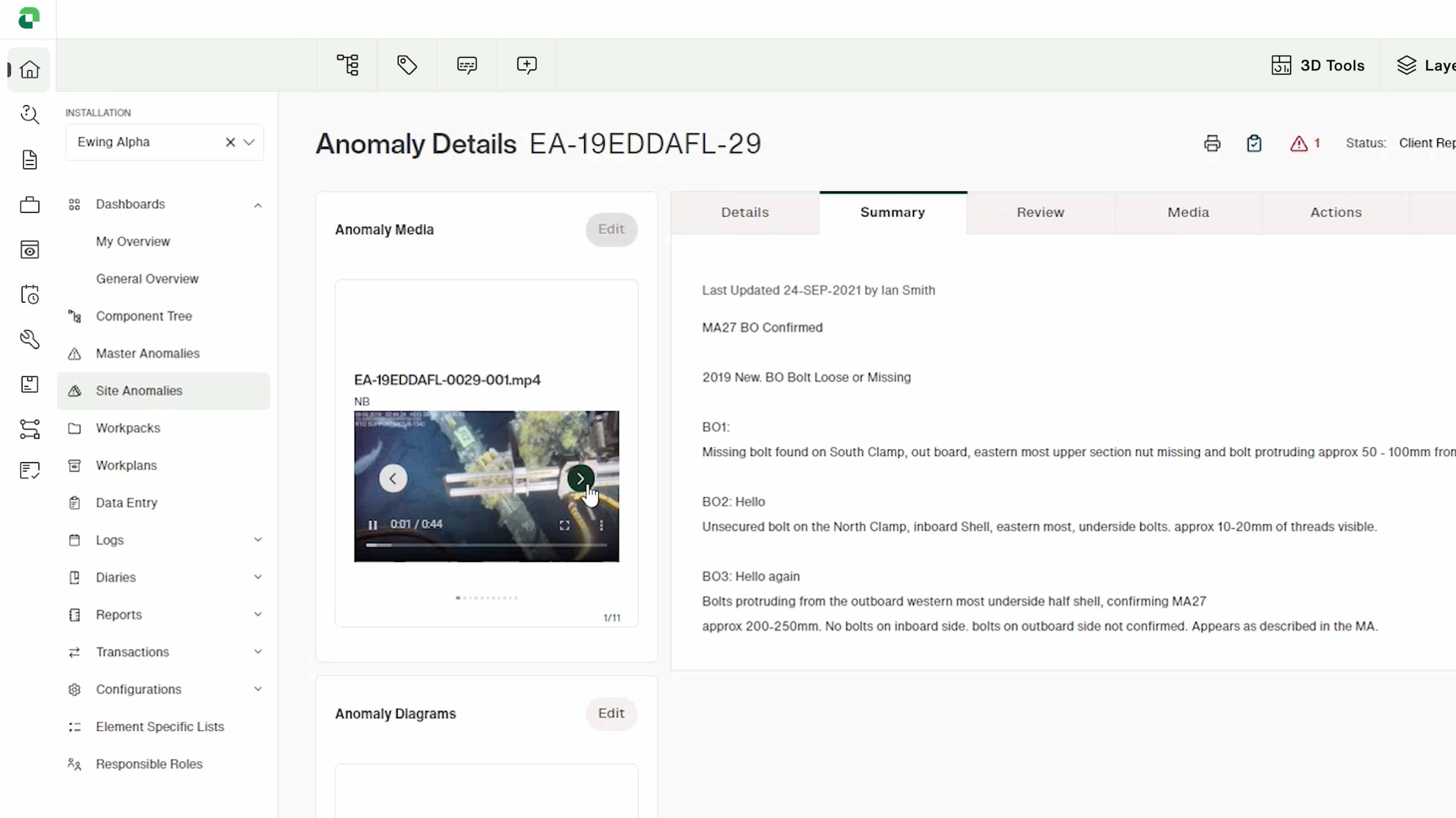

Accurate state of the nation

By accessing all your operating and supporting engineering data in one place, Aize allows you to quickly assess barriers, cumulative risk and ultimately the integrity and performance of your asset. Operators get a holistic view of their facilities' state and condition, increasing confidence in decision-making.

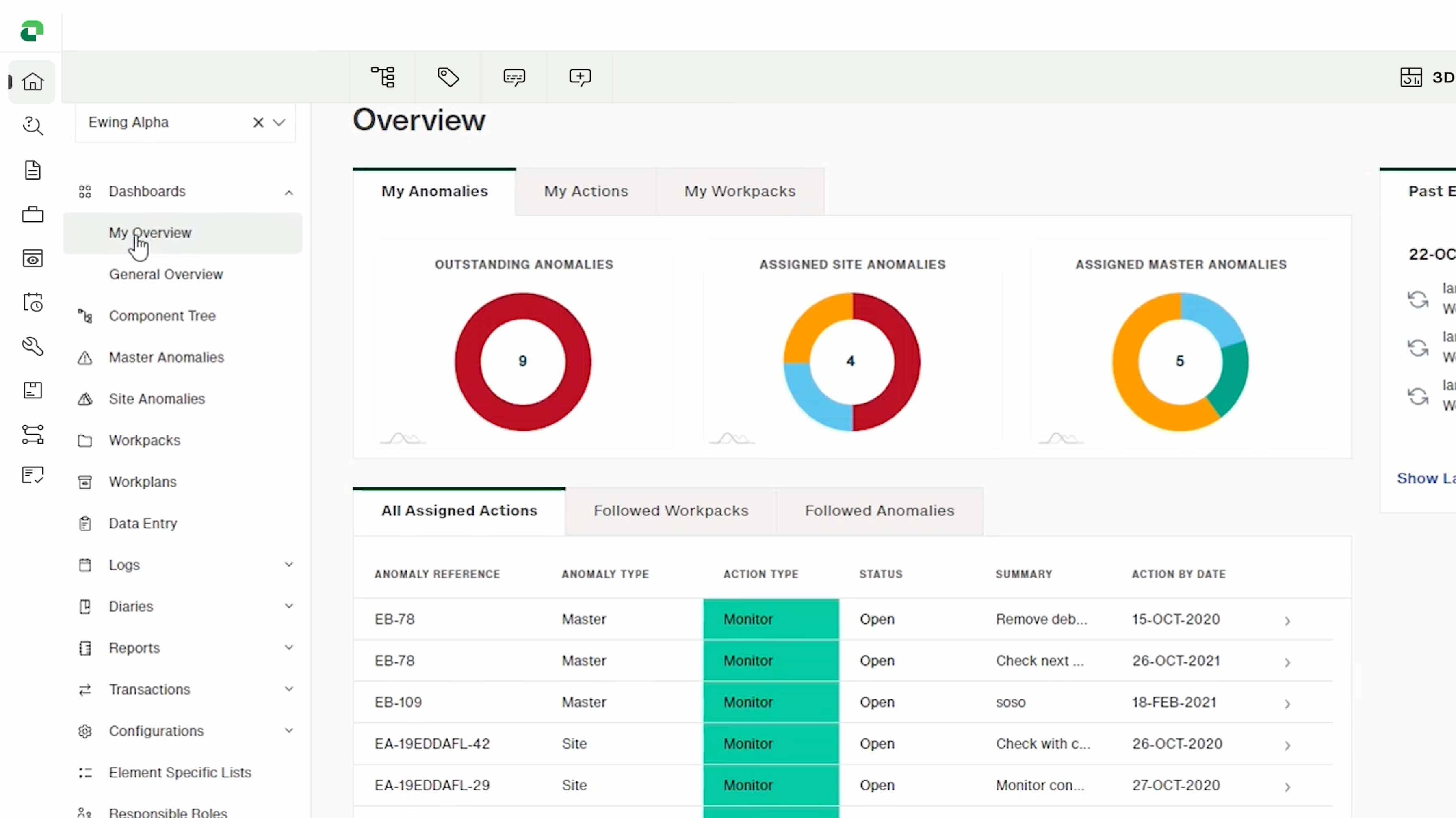

MAINTENANCE PLANNING

No more planning in the dark

Moving away from multiple source systems to a single shared environment lets you visualise, sort, filter and optimise your activity plans in one holistic view. Be it regular sprints, work orders, maintenance, or turnarounds, Aize enables you to look at the totality of your projects. Deal with interfaces, isolations and resource loading before it’s too late.

EFFECTIVE EXECUTION

Bringing teams together

Out in the field, Aize lets industrial workers retrieve all information related to scheduled tasks and activities, such as P&IDs, technical documents, history and checklists. Anyone can annotate and comment directly in Aize should models be inaccurate, have missing data, or have unclear plans. Whether you operate offshore or onshore, Aize helps connect managers, planners and technicians.

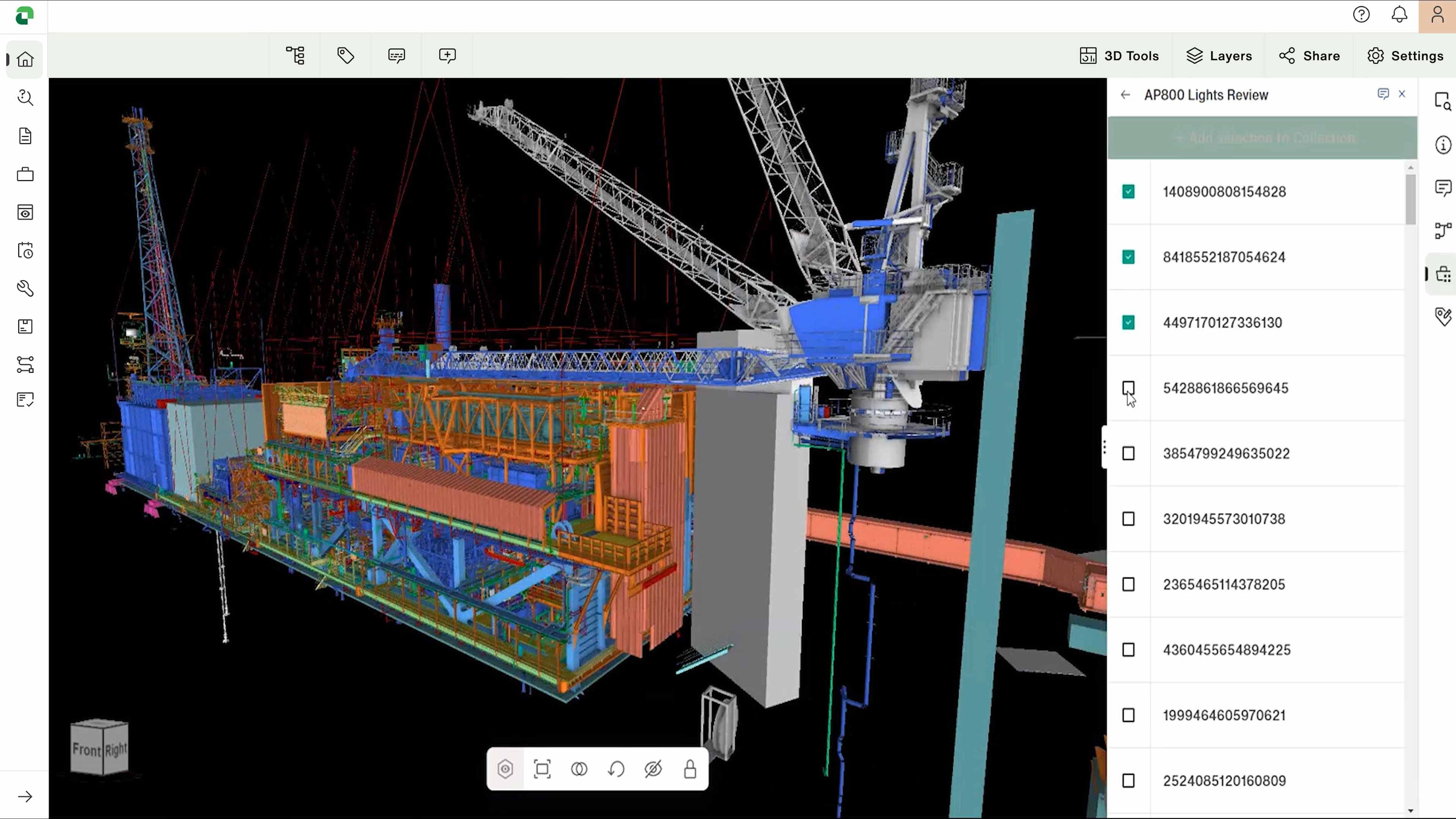

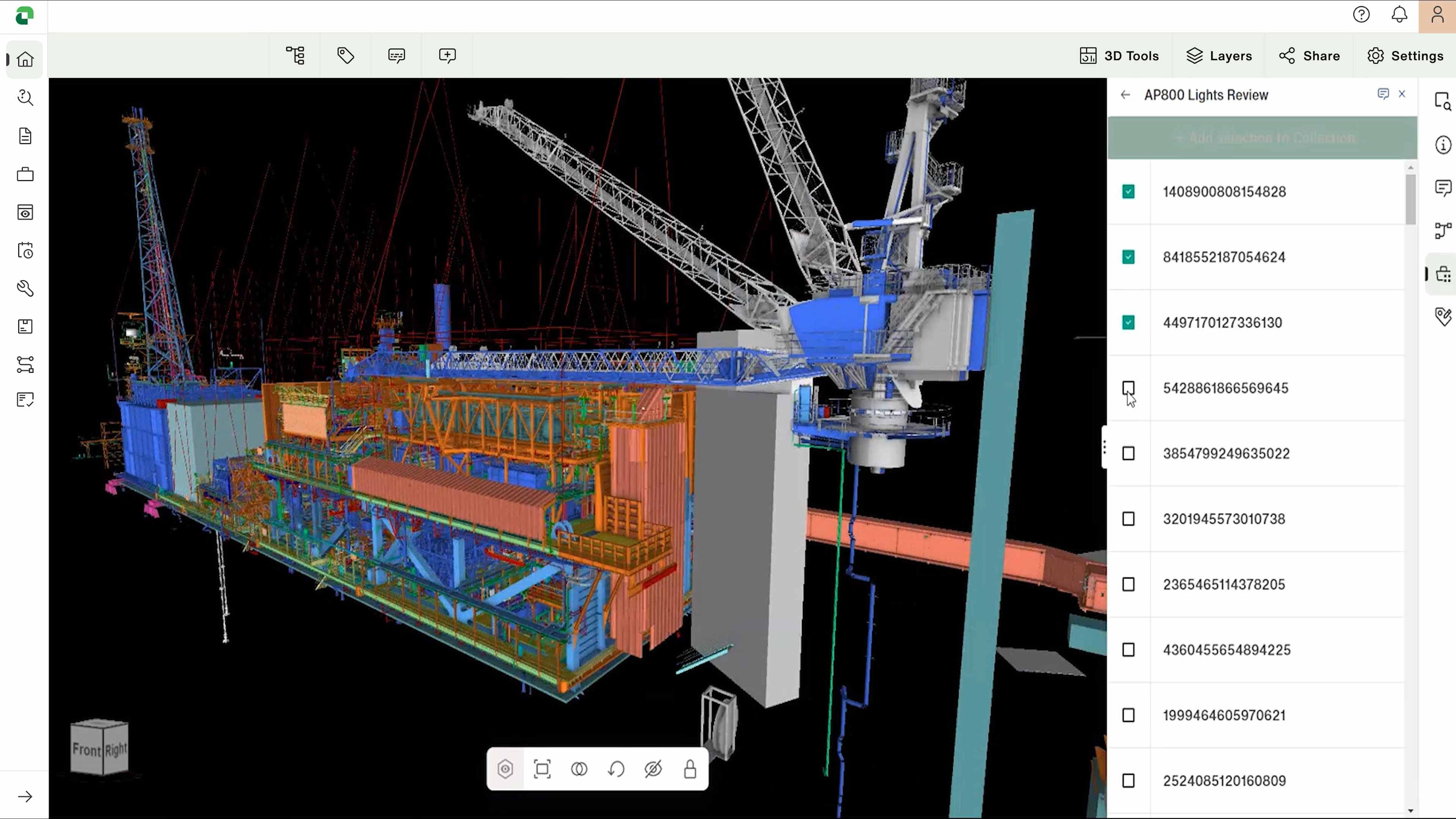

VISUALISE YOUR WORLD

Total overview in seconds

Aize defeats siloed spreadsheets, PDFs and email threads scattered across multiple sources. Understand the current state of your assets by gaining visibility of all critical issues at a glance. No more endless rows in a sheet, numbers in a document or symbols on a drawing. Aize visualises and overlays all that in 2D or 3D to advance your insights.

Bringing the facility to your fingertips

Visualise your assets

Aize streamlines and visualises your data to map out your asset's information in one holistic view. Display a digital twin of your asset and view it in whatever perspective fits your expertise.

-

View in 2D or 3D

-

Connect media, visuals, photogrammetry or point cloud

-

Utilise visualisation tools to improve isolation planning

-

Plan and execute the maintenance and turnaround planning through visual aids

Navigate the sea of information

Search and find information quickly directly in Aize – regardless of technical abilities. A single source of truth removes barriers between data sets and helps you make sense of an ever-increasing volume and complexity of data.

-

Global search through all asset and equipment data

-

Clickable drawings (P&IDs) and documents connected to the 3D view

-

Access equipment properties with a click of a button

-

Interpret multiple data sources from one place

Collaborate with purpose

Gain a better collective understanding of where you are - both in place and time. Aize enables teams to chat, share links, exchange files and interact with the digital twin together - and increase its data quality and completion by doing so.

-

Invite both internal and external third-party users

-

Comment on objects directly in the model

-

Collaborate on drawings, documents and interfaces

-

Group objects with common traits to plan and review activities

Optimise through specialist tools

Aize helps you access modules and specialist tools to solve domain-specific tasks to plan, schedule and optimise workflows. From maintenance planning to integrity management and anywhere in between.

-

Plan and execute maintenance and turnaround projects

-

Gain insights to manage barriers and cumulative risk

-

Optimise inspections and monitor asset performance

-

Plan and perform lifting and rigging operations

Integrate third-party systems

Your existing applications coexist with Aize. Structuring and contextualising the data enables you to gain a single source of truth for your asset while continuing to make the most of the tools you’ve already invested in.

-

Integrate your source systems

-

Structure and contextualise data through a common data model

-

Access third-party specialist tools from Aize

-

Streamlined data onboarding shortens time to value

See things differently

We have felt your pain

Aize has been developed by and for domain experts, based on 30 years of software experience and 180 years of industrial heritage in the Norwegian Aker group.

The latest news from Aize

We’re changing the game, and we’re excited to share our journey with you.